Building & Installation

Delivering safe, efficient building and installation services for upstream oil & gas facilities with proven track record across onshore and offshore operations.

Delivering safe, efficient building and installation services for upstream oil & gas facilities with proven track record across onshore and offshore operations.

Our building and installation teams deliver turnkey solutions from fabrication through commissioning. With expertise in both onshore and offshore environments, we execute projects safely, on schedule, and within budget while maintaining strict adherence to HSE standards and NCDMB local content requirements.

Complete building and installation capabilities for upstream facilities

Quality fabrication for process modules and structures

Equipment and piping installation expertise

Complete E&I installation and commissioning

Foundation and infrastructure construction

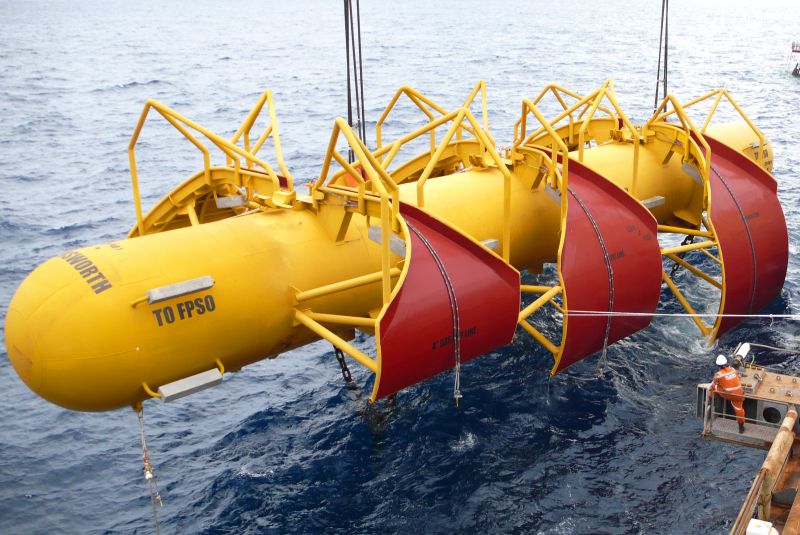

Specialized offshore construction capabilities

Comprehensive documentation for construction excellence

Comprehensive construction strategy including schedule, resource allocation, subcontractor management plan, quality control procedures, and HSE management plans. Includes detailed method statements for all critical activities and risk assessments.

Complete safety documentation including site-specific HSE plan, HAZOP and risk assessments, permit-to-work procedures, emergency response plans, and safety training records. Includes toolbox talk schedules and safety performance tracking.

Complete QA/QC records including material certificates, welding procedure specifications, welder qualifications, NDE reports, hydrostatic test records, and inspection reports. All documentation traceable to project specifications.

Complete as-built drawings including P&IDs, isometrics, electrical single lines, loop drawings, and structural modifications. Red-lined drawings compiled into final deliverables with all field changes documented and verified.

Systematic documentation of all commissioning activities including ITRs, system completion certificates, functional test results, performance test data, and punch list closure documentation. Includes commissioning procedures and operator training records.

Complete operations and maintenance manuals for all installed equipment and systems. Includes vendor documentation, spare parts catalogs, preventive maintenance schedules, troubleshooting guides, and documented operator training programs with competency assessments.